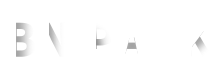

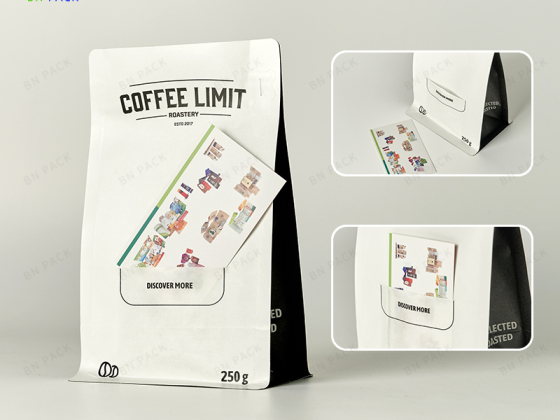

Coffee Stand Up Pouch

BN PACK focuses on food packaging bags, self-supporting nozzle bags, aluminum foil bags, daily chemical nozzle bags, modern plastic flexible packaging integrating color printing and bag making. It has a large-scale production enterprise and is a one-stop product development, design and production. service.

- OEM & ODM

- China

- 5 DAYS

- 600000 PCS

- Information

The stand up pouch is a plastic flexible packaging bag with a horizontal support structure at the bottom. It can stand on its own without any support. The stand pouch is a relatively novel packaging form. , preservation and airtightness have advantages. Ordinary stand-up pouch: a common form of stand up pouch, in the form of four-sealed edges, non-reclosable and repeated opening, this stand up pouch is generally used in the industrial supplies industry.

Stand up pouch with zipper: The self-supporting bag with zipper can be reused. Since the zipper is not closed and the sealing strength is limited, this form is not suitable for packaging liquids and volatile substances. It is divided into four seals according to different edge sealing methods. There are two kinds of edge sealing, three edge sealing, and four sealing edges, which means that the product packaging has a layer of ordinary edge sealing in addition to the zipper seal when it leaves the factory. The method solves the disadvantage that the strength of the zipper edge is small and is not conducive to transportation, while the three-sided edge is directly sealed with the zipper edge, which is generally used to hold light products,etc.

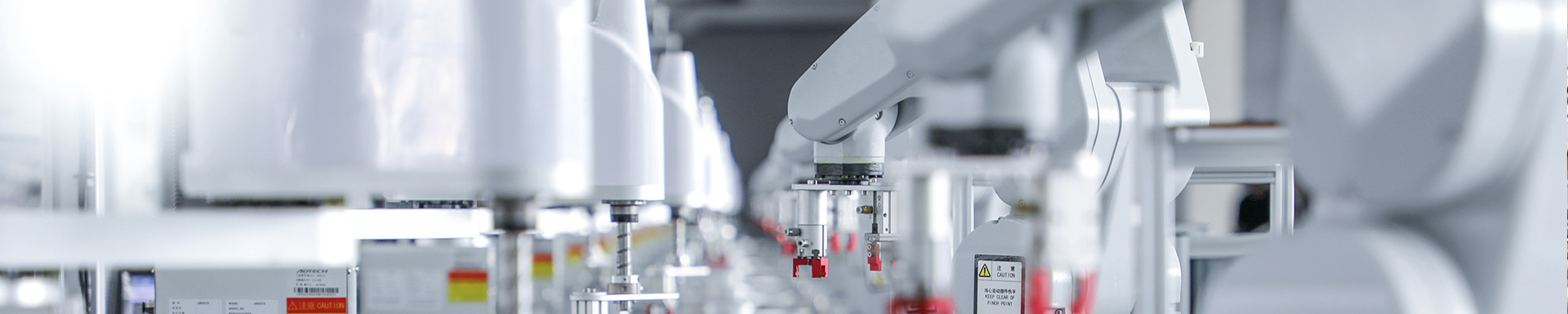

We use HP digital printer,HP indigo digital printer uses the electrostatic imaging principle, but does not use dry toner ink, but wet electronic ink. First, charge the imaging board evenly, and then the laser head discharges the laser beam on the imaging board according to the dot matrix format of the color after rip processing. The electronic ink of the color will adhere to the imaging area of the imaging board under the action of electric field force to form an image layer. The image layer is also transferred to the blanket through the potential difference between the imaging drum and the blanket drum. The electronic ink is partially dissolved after heating on the blanket, transferred to the substrate by pressure, and then solidified and attached to the substrate. The imaging process of other colors is the same, and it is realized on a group of rollers.